Barco and Vogel's respond to Digital Twin Control Room requirements

The room of this project of the University of Ghent presented special conditions to install a videowall, configured with OverView KVD5521B displays, that Vogel's solved with a tailor-made solution based on Connect-it.

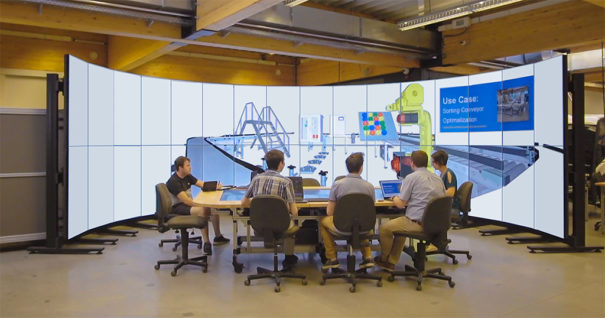

Visualization is a great asset when trying to design or optimize an industrial manufacturing process, but it is difficult to establish a suitable environment. Not only is a way to visualize the drawing needed, it is also necessary to have an immersive overview that shows in a realistic and attractive way how to adapt and apply the changes to the virtual model.

To this end, the Digital Twin Control Room was created, a project of the Industrial Systems Engineering research group of the University of Ghent (Belgium).

Established on its campus in Kortrijk, this project has been carried out with the screens of ship (visualization), the assembly solutions of Vogel's and integration was carried out by Axians Audiovisual Belgium in Lucodex.

In order to create the best solution to visualize the process, it was important to give the screens a curvature of 180 Degrees. However, there was a restriction of not being able to anchor the solution due to the underfloor heating elements of the building. To solve this situation Vogel's created a custom structure based on the universal Connect-it system.

For the configuration of the videowall have been used the Screens OverView KVD5521B of Barco. Modular LCD equipment that has been mounted in portrait mode to create the curve.

To create an immersive effect, the images are displayed on the videowall as a circular canvas. Every four screens (2 superior and 2 Lower) changes the point of view, so a person standing in the middle can easily look and feel part of the virtual world.

The visualized process can be controlled with the help of touch screens located on the table and a control knob. This technology boasts a videowall that is not connected by cable to the physical automation process, and all content and tasks are performed wirelessly.

You liked this article?

Subscribe to our RSS feed And you won't miss anything.