Porsche establece nuevos estándares de calidad gracias a la realidad aumentada

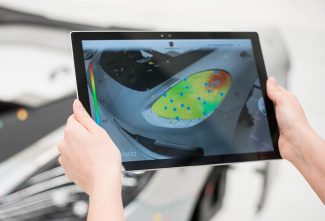

En el Inno-Space de Leipzig se ha implementado una solución de realidad aumentada que permite, a través de tablets, verificar el diseño y producción de un coche y conseguir un óptimo control de calidad.

Durante los últimos 70 years, Porsche ha sido sinónimo de construcción de autos deportivos al más alto nivel y con un excelente estándar de calidad. Este mes de febrero, la empresa alemana ha puesto en marcha en el área de innovación (Inno-Space), que acaba de abrirse en las instalaciones de Leipzig, una experiencia desarrollada con realidad aumentada que persigue obtener la máxima calidad de sus vehículos.

Esta solución se ha implementado en el proceso de producción y busca conseguir un medio rápido y fiable para resaltar las desviaciones del nivel de perfección especificado, lo que permite un ahorro de tiempo y un aumento significativo en la calidad del análisis.

Esta solución se ha implementado en el proceso de producción y busca conseguir un medio rápido y fiable para resaltar las desviaciones del nivel de perfección especificado, lo que permite un ahorro de tiempo y un aumento significativo en la calidad del análisis.

El equipo de Inno-Space colabora con varias universidades y nuevas empresas. En asociación con GTV, una start-up con sede en Dresde, Porsche ha utilizado la realidad aumentada como una plataforma técnica para el control de calidad.

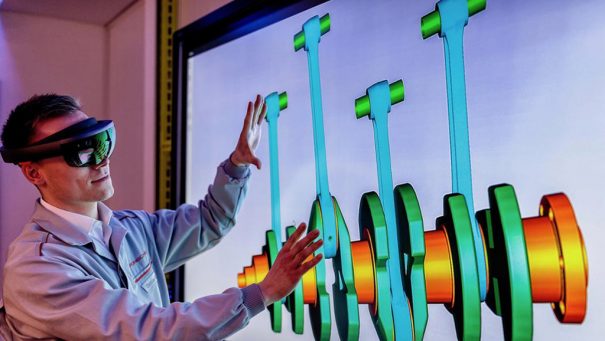

El Inno-Space es un punto de encuentro entre el presente y el futuro para el control de calidad, desarrollando innovaciones que puedan transferirse a los procesos de producción en serie en la planta. En esta área, se puede simular un entorno de fábrica TI, que luego se conecta a la planta de forma controlada con el fin de integrar los nuevos desarrollos en el proceso de producción.

Un equipo interno de TI que trabaja en colaboración con el equipo de gestión de la calidad es la fuerza impulsora que está detrás de estas nuevas tecnologías, aplicaciones y procesos. “En Inno-Space podemos diseñar y probar conceptos pioneros para el futuro sin interrumpir los procesos normales de la planta”, dice Albrecht Reimold, miembro de la Junta Ejecutiva de Producción y Logística de Porsche AG.

Un equipo interno de TI que trabaja en colaboración con el equipo de gestión de la calidad es la fuerza impulsora que está detrás de estas nuevas tecnologías, aplicaciones y procesos. “En Inno-Space podemos diseñar y probar conceptos pioneros para el futuro sin interrumpir los procesos normales de la planta”, dice Albrecht Reimold, miembro de la Junta Ejecutiva de Producción y Logística de Porsche AG.

GTV ha trabajado junto con la Fraunhofer Society para desarrollar una aplicación para tablet que toma los defectos encontrados durante la prueba de aspecto y percepción y los superpone sobre una imagen del vehículo en cada etapa del proceso de producción. Los datos CAD individuales del vehículo se leen en la aplicación y la cámara de la tablet se mantiene sobre un componente. La imagen de CAD se superpone a la imagen en directo, haciendo que los defectos o las desviaciones sean inmediatamente visibles.

La base de datos también incluyen detalles de otros parámetros, como articulaciones. In this case, la comparación de la imagen en tiempo real con la imagen CAD resalta directamente cualquier área que no cumpla con el estándar requerido.

Otra ventaja es que el proceso de prueba se puede transmitir en tiempo real a cualquier socio o sitio. At the same time, los defectos detectados se almacenan en la base de datos central de la planta y se ponen a disposición en todo el mundo.

“El que la tablet esté conectada a la red nos permite hacer cosas como auditorías de calidad con nuestros proveedores a través de videoconferencia”, explica Andreas Schmidt, Jefe de Calidad de la planta de Porsche en Leipzig y responsable de implementar el proyecto de realidad aumentada.

Did you like this article?

Subscribe to our NEWSLETTER and you won't miss anything.