ArKaos provides automatic visual and lighting control in KlingNet3

El nuevo protocolo KlingNet3 desarrollado por ArKaos ofrece un sencillo y flexible control visual y de iluminación en su aplicación en la industria de entretenimiento.

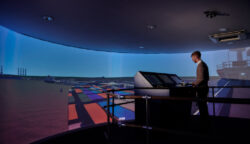

Presentado durante la reciente participación de ArKaos in Prolight+Sound 2023, el nuevo protocolo estuvo funcionando con cincuenta dispositivos en una red KlingNet3 a través del control MediaMaster para demostrar la estabilidad y solidez del sistema.

KlingNet3 (patent pending) permite controlar todos los parámetros de un dispositivo de iluminación y mucho más, which makes it a alternativa viable a DMX en la industria.

Desarrollado para el mapeo de píxeles de los dispositivos de iluminación y ampliamente implementado por la mayoría de los fabricantes de este sector, la versión KlingNet2 ha sido un gran éxito en los últimos doce años, si bien se limitaba a controlar únicamente la información de píxeles de intensidad y color de una luminaria.

KlingNet3 introduce importantes funciones adicionales, like the detección automática de dispositivos y sus tipos en la red; actualizaciones de software, cambio de modo remoto y otras funciones “que responden a las demandas de diseñadores de iluminación y visuales, programadores y usuarios finales, combinada con una exhaustiva investigación durante los últimos tres años”, señalan desde ArKaos.

KlingNet3 introduce importantes funciones adicionales, like the detección automática de dispositivos y sus tipos en la red; actualizaciones de software, cambio de modo remoto y otras funciones “que responden a las demandas de diseñadores de iluminación y visuales, programadores y usuarios finales, combinada con una exhaustiva investigación durante los últimos tres años”, señalan desde ArKaos.

Basado en tecnologías estándar en la nube, KlingNet3 permite gestionar más datos de los que utilizan actualmente incluso los mayores espectáculos, “ya que están construidos para el futuro. Los fabricantes tendrán la opción de elegir qué funciones de este protocolo habilitan en sus nuevos productos”.

Una característica importante es que todas las funciones de la luminaria se mantienen dentro de la misma y se comparten a través del protocolo con las consolas de iluminación y los servidores de medios.

En la información de la luminaria del sistema se puede incluir un modelo de malla 3D completo que se pone a disposición de los visualizadores y sistemas de seguimiento, junto con la de color, enlaces al manual y detalles de todos los gobos, ruedas de animación y otros efectos.

Todo ello hace que se pueda modelar con precisión el movimiento y los efectos de la luminaria en el visualizador. Un modo de control de bucle cerrado permite a la consola adquirir todos los valores reales de la luminaria, pero también enviar un aviso a esta si algo está fuera de lugar.

Esta información detallada puede referirse a parámetros específicos e incluir elementos como voltajes, corriente, potencia de la lámpara, las horas que ha estado funcionando una fuente de luz, las RPM de los ventiladores, la temperatura interna, etc; información muy valiosa para los técnicos de sistemas, que se comunicará a través de KlingNet3.

As pointed out Koen Buys, director de desarrollo de productos de ArKaos, “ya hay quince fabricantes se han suscrito a KlingNet3 y tras la feria este número ha aumentado. La idea que subyace en el desarrollo de este protocolo es hacer avanzar la industria y responder a las necesidades futuras”.

KlingNet3 estará disponible bajo una licencia similar a la de KlingNet2 y se ha diseñado para que sea asequible para todos. “Queremos democratizar y hacer que el control de la iluminación sea tan fácil de configurar como una luz inteligente o un sistema táctil de un solo botón. Rápido, sencillo y fiable, que funcione siempre”, afirma Buys.

Cuando las luminarias se conectan a la misma red informática, el sistema las detecta automáticamente, las añade a la consola de control y están inmediatamente disponibles para su control. KlingNet3 facilita los escenarios multiusuario for broadcasts, espectáculos en directo complejos, festivals, etc. en los que a menudo hay varias consolas en funcionamiento o en sesión.

Los parámetros de las luminarias se pueden dividir para que los elementos seleccionados puedan controlarse, For example, por operadores remotos, mientras que otros relacionados con la misma luz se pueden ejecutar desde la consola de iluminación.

Diseñado desde el principio para ser compatible con la nube, permite que todas las funciones de KlingNet3 se conecten a través esta, lo que resulta idóneo para el control en diferentes equipos y que los instaladores instalen sin problemas actualizaciones de software o mantenimiento preventivo.

KlingNet3 es compatible con la transmisión en directo, por lo que los dispositivos de iluminación locales pueden sincronizarse con un sistema global procedente de la transmisión host a través de la nube.

Besides, desde la infraestructura de la nube es posible recopilar datos detallados a través de KlingNet3 para que los fabricantes puedan ver cómo se utiliza su kit una vez vendido, For example, registra cuántas veces utilizan los usuarios finales parámetros como encofrados, gobos, prismas, etc., lo que puede ser útil para afinar futuros planes de I+D.

Did you like this article?

Subscribe to our NEWSLETTER and you won't miss anything.